PRODUCTION

QUALITY CONTROL

Our Quality Control Deparment Consists of Raw Quality Control Department and Finished Quality Control Department.

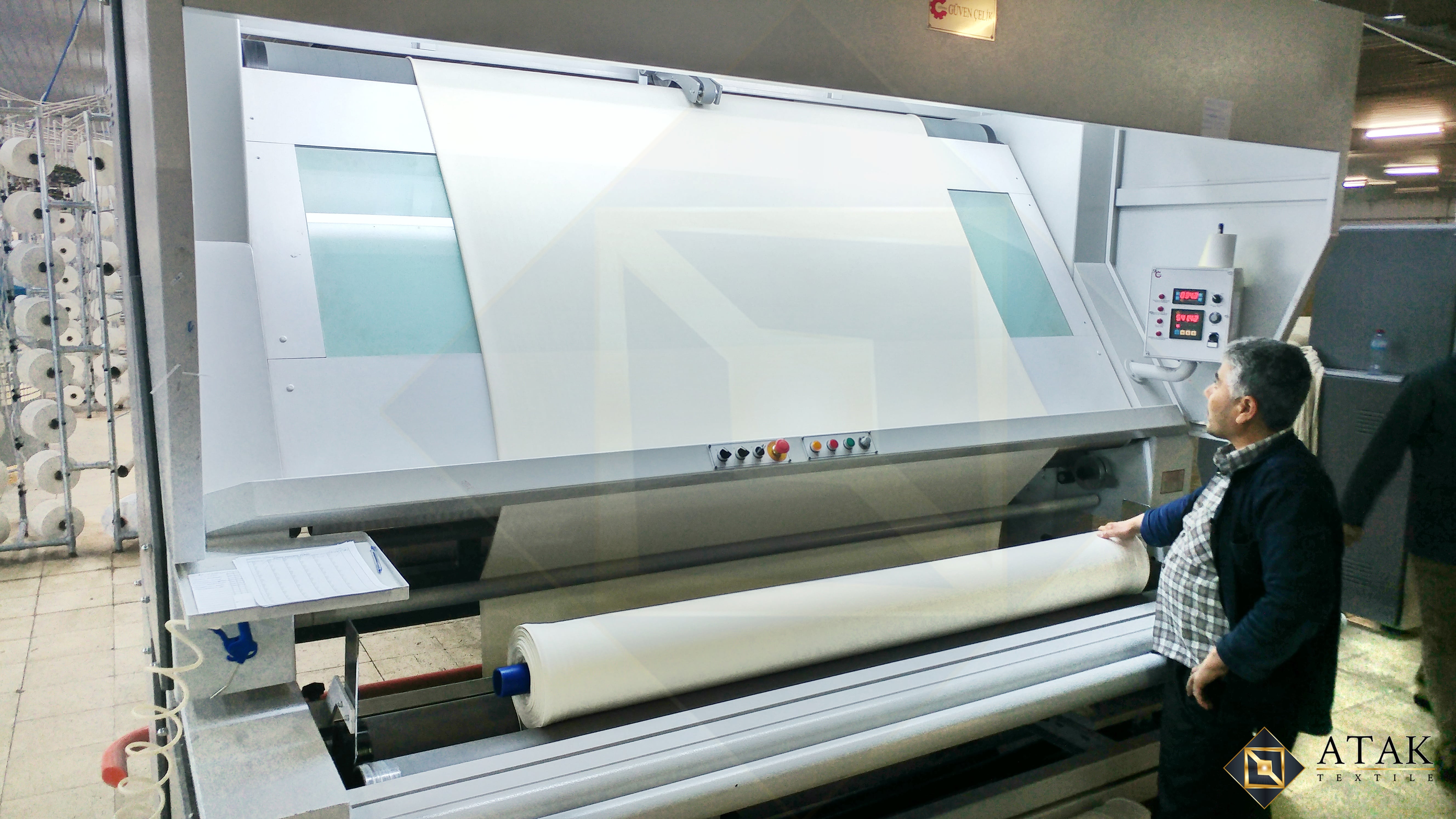

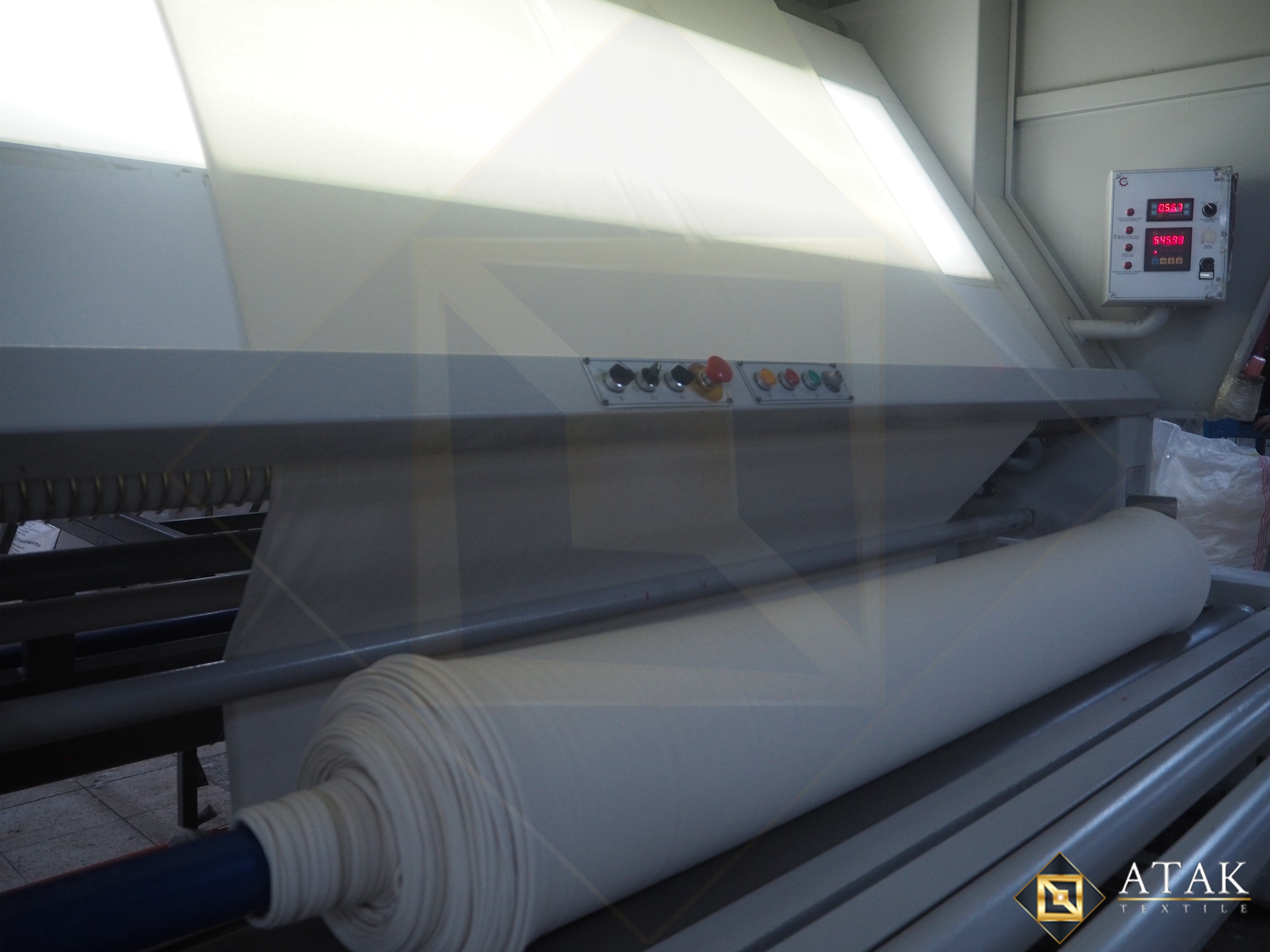

Every each roll of fabric is inspected by quality control staff right after knitted.

In-Process Quality Control is implemented during dyeing and finishing processes. Each roll of Finished fabrics are visually checked and physically & chemically tested.

The tests and controllings that laboratuary implements are; colour controlling (by specktrophotometer and by eyes), dimensional change after washing-shrinkage, spirality after washing, hand feeling-touch, colour fastness, water fastness, perspiration fastness, rubbing fastness, pilling resistance test, pH, GSM, width and tensile strenght tests.

Samples from each lot/party fabrics are kept for 3 months after sent to customers, in order to solve unexpected situations.